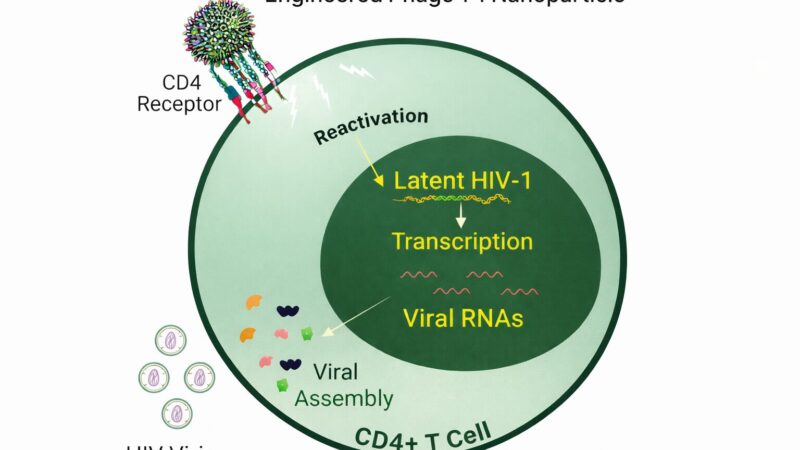

We know that phages — viruses that kill bacteria —are beneficial to us, and active and robust studies are underway to develop them. However, have you ever considered that phages can also be harmful, killing the beneficial bacteria that are essential to the entire biological process?

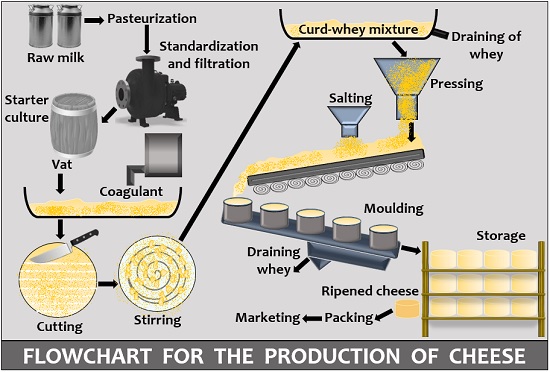

Yes, you read it right…Lactococcus lactis bacteria used in the fermentation of food, especially yoghurt, cheese, make a very robust defense against phages called Audmula. These defense systems act against phages — viruses that can disrupt cheese and yoghurt fermentation and cause quality and product losses in the dairy industry.

Phage outbreaks are the most common challenges faced in the dairy industry. It is essential to control phage contamination to address real-world challenges in dairy manufacturing.

The study was conducted by DSM-Firmenich, APC Microbiome Ireland, the French National Research Institute for Agriculture, Food and Environment (INRAE), and published in Proceedings of the National Academy of Sciences (PNAS).

In a recently published interview in Food Ingredients First, Noël van Peij, co-author and principal scientist at DSM-Firmenich, discusses the urgent need to develop resilient, robust antidefense systems like Audmula in the dairy industry. “Contamination typically occurs when phages enter the production environment via raw milk, while recycling, or due to insufficient sanitation. Maintaining phage control in dairy processing requires continuous attention to hygiene, ingredient handling, and the rotation of phage-resistant cultures to mitigate the diverse phages that can enter production settings,” says Noël van Peij.

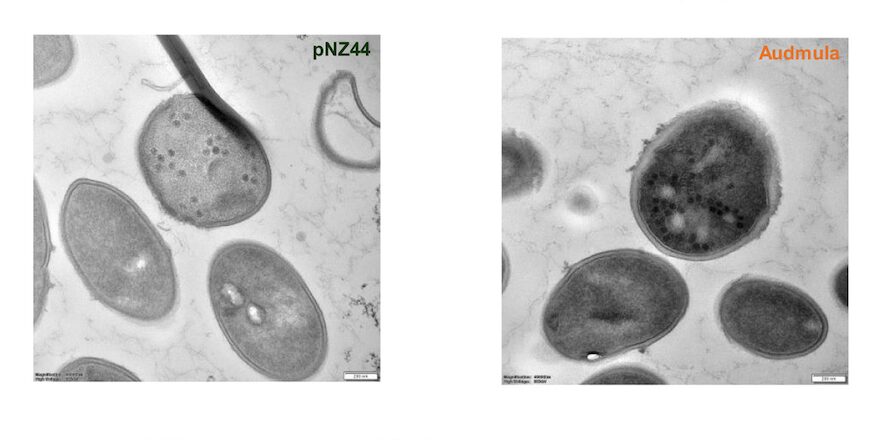

When asked how Audmula’s defense system works? –He says, “The Audmula defense system represents a novel mechanism that modifies and thickens the bacterial cell wall. After infection, once hundreds of new phage particles have assembled inside the cell, the phage release mechanism becomes inactive due to the modifications in the bacterial cell wall.

As a result, the mature phages remain trapped within the infected cell, preventing their spread during fermentation.” This will help the fermentation process to continue without any halt, preventing any loss of time and money on a large scale.

The study reveals the complex interplay between bacterial defense and viral counter-strategy. For the study, Lactococcus strains and phages were sourced directly from active dairy environments, grounding the research in authentic production conditions. The team identified new anti-phage systems and validated them under production-like conditions.

Finally, Noël van Peij says, “the next phase will integrate these findings into the culture development toolbox to deliver more tailored, phage-robust solutions for dairy manufacturers.”

“The next phase will integrate these findings into the culture development toolbox to deliver more tailored, phage-robust solutions for dairy manufacturers”

Noël van Peij

This study in a real-world scenario plays a more vital role in the control of phage menace in the dairy industry. Industry-academia collaborations are paramount to address real-world challenges in dairy manufacturing. More such studies are fundamental to controlling economic losses across industries, which shall include ongoing monitoring and innovation.

Leave a Reply

You must be logged in to post a comment.